- Αρχική

- Εταιρεία

- Προϊόντα

- Black Friday

- DRONES

- Photogrammetry Seminars

- GeoSense UAS Academy

- ΔΕΚΤΕΣ GPS/GNSS

- ΧΕΙΡΙΣΤΗΡΙΑ ΠΕΔΙΟΥ

- ΤΟΠΟΓΡΑΦΙΚΑ ΟΡΓΑΝΑ

- ΦΑΣΜΑΤΙΚΕΣ ΚΑΜΕΡΕΣ

- 3D LASER ΣΑΡΩΤΕΣ

- 3D ΟΠΤΙΚΟΙ ΣΑΡΩΤΕΣ

- ΤΕΧΝΙΚΟ ΛΟΓΙΣΜΙΚΟ

- ΘΕΡΜΟΚΑΜΕΡΕΣ

- ΠΑΝΟΡΑΜΙΚΕΣ ΚΑΜΕΡΕΣ

- ΓΕΩΡΑΝΤΑΡ

- 3D PRINTERS

- ΑΔΡΑΝΕΙΑΚΑ ΣΥΣΤΗΜΑΤΑ

- ΗΧΟΒΟΛΙΣΤΙΚΑ

- ΚΑΤΑΣΚΕΥΑΣΤΙΚΑ LASER

- ΑΠΟΣΤΑΣΙΟΜΕΤΡΑ

- ΦΟΡΗΤΟΙ ΣΤΑΘΜΟΙ ΕΝΕΡΓΕΙΑΣ

- ΔΙΚΤΥΟ ΣΤΑΘΜΩΝ ΑΝΑΦΟΡΑΣ

- Airborne LiDARs

- ΜΕΤΑΧΕΙΡΙΣΜΕΝΟΣ ΕΞΟΠΛΙΣΜΟΣ

- UAS Academy

- Ερευνητικά Έργα

- Εταιρικά Νέα

- e-Shop

- Υπηρεσίες

- Επικοινωνία

- επικοινωνία

- Sitemap

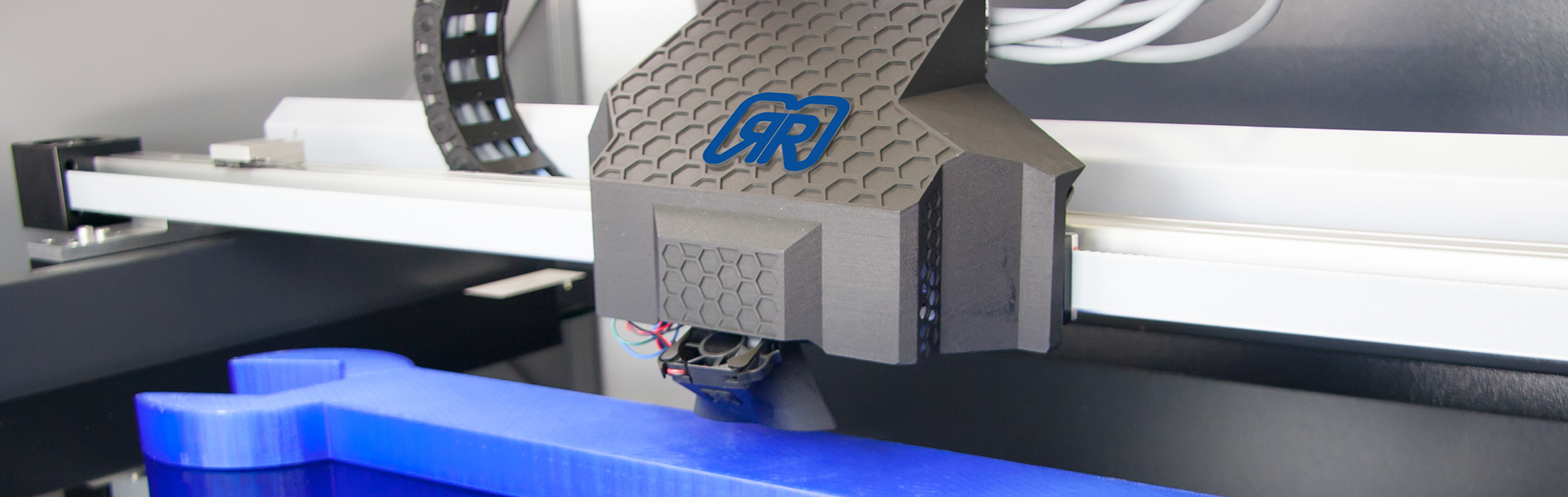

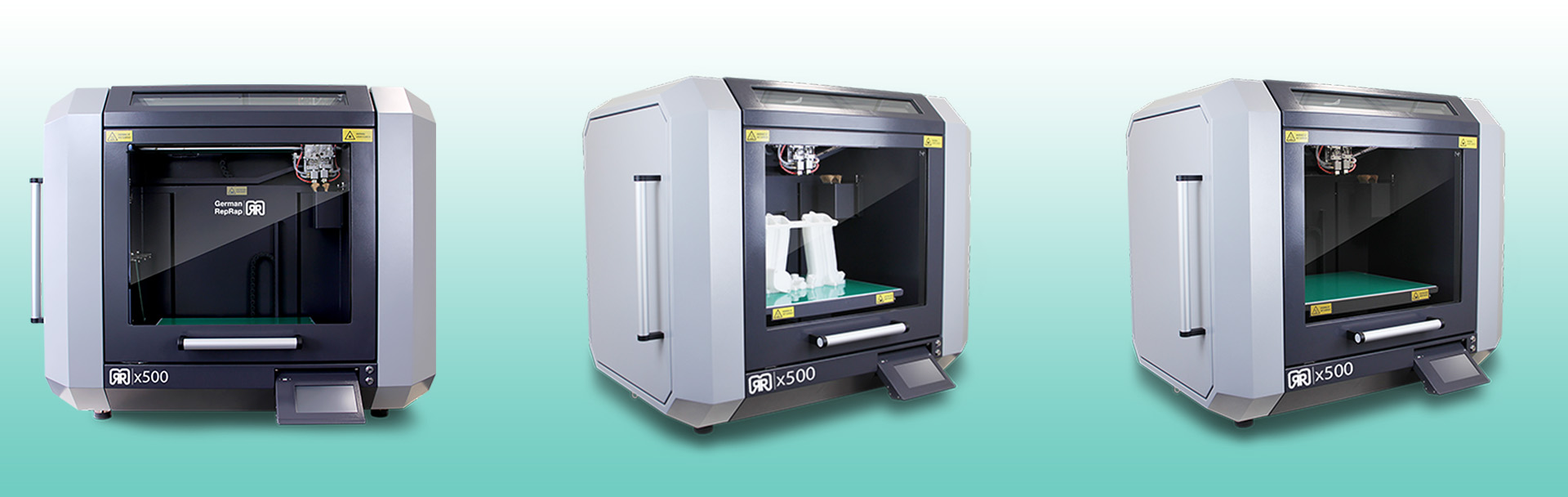

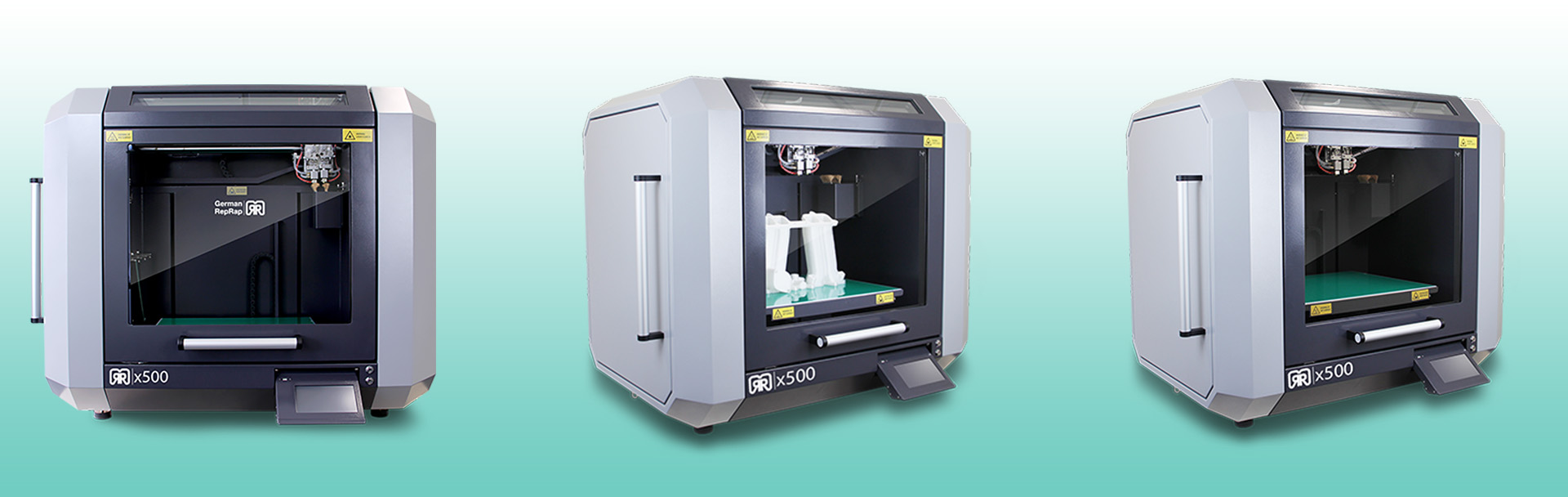

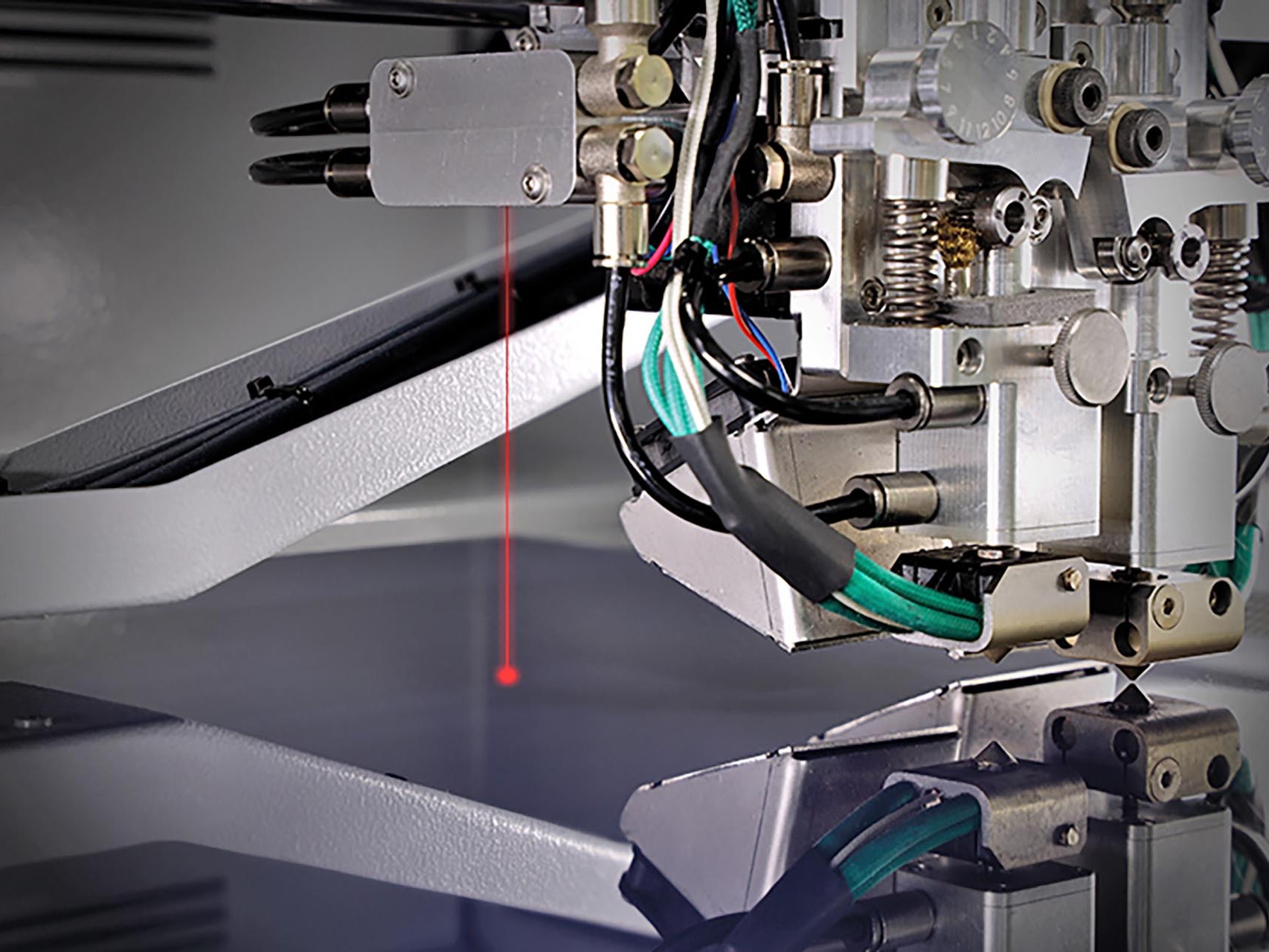

RepRap x500pro 3D

The x500pro is a fully assembled large-volume 3D printer loaded with all new features necessary for professional use. Print intricate models up to 500 x 400 x 475 mm in size with a layer height of down to 20 microns with engineering grade materials!

Unbeatable reliability for industrial applications

The x500pro is the solution for serial printing high-quality materials such as high-temperature, abrasive and other materials. In addition to a large build volume of 500 x 400 x 450 (X/Y/Z) mm, it incorporates additional innovations that are essential for industrial applications.

New options in terms of dimension and shape

The x500pro offers a whole new level of freedom when it comes to construction and enables the production of complex structures.

Precision in continuous operation

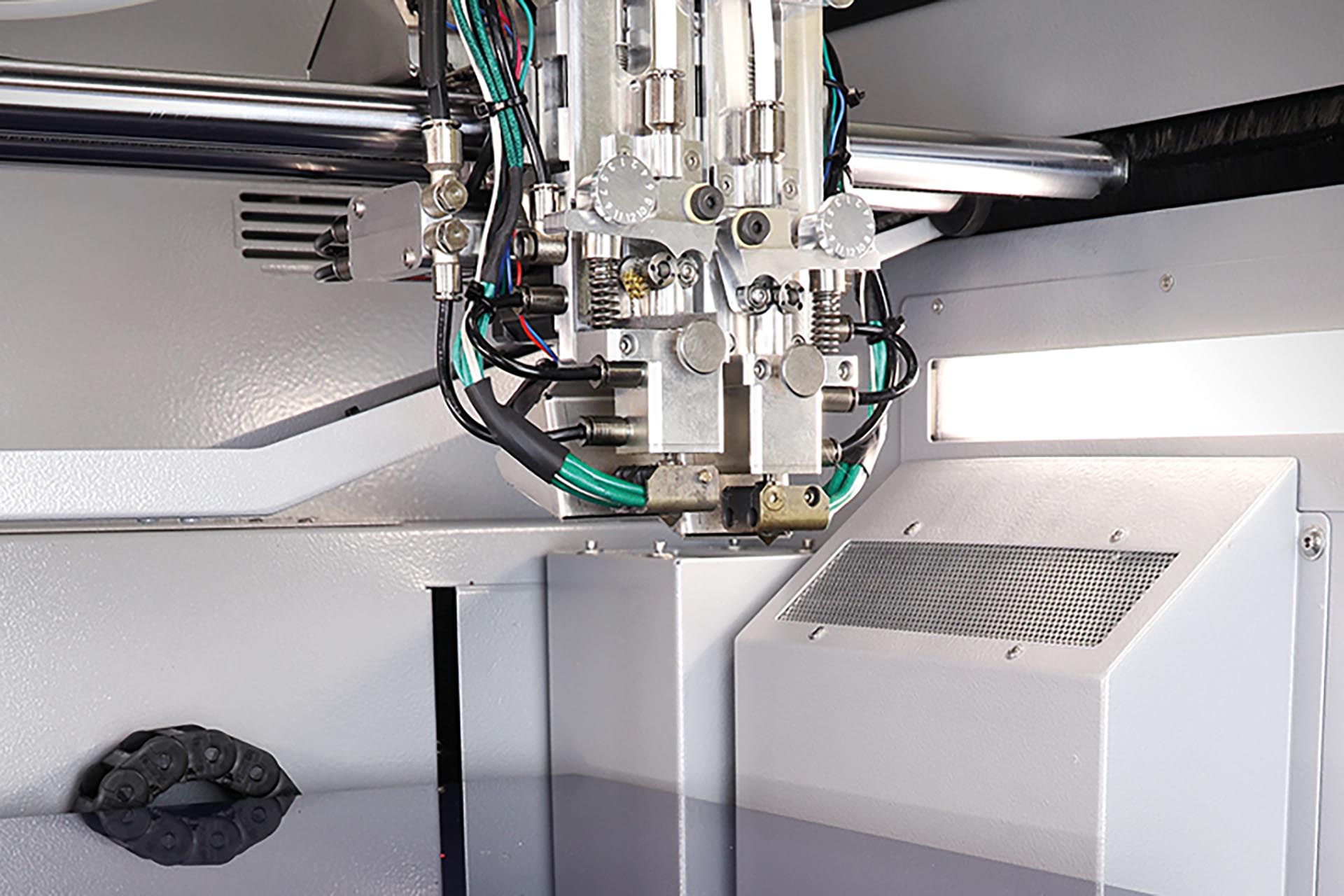

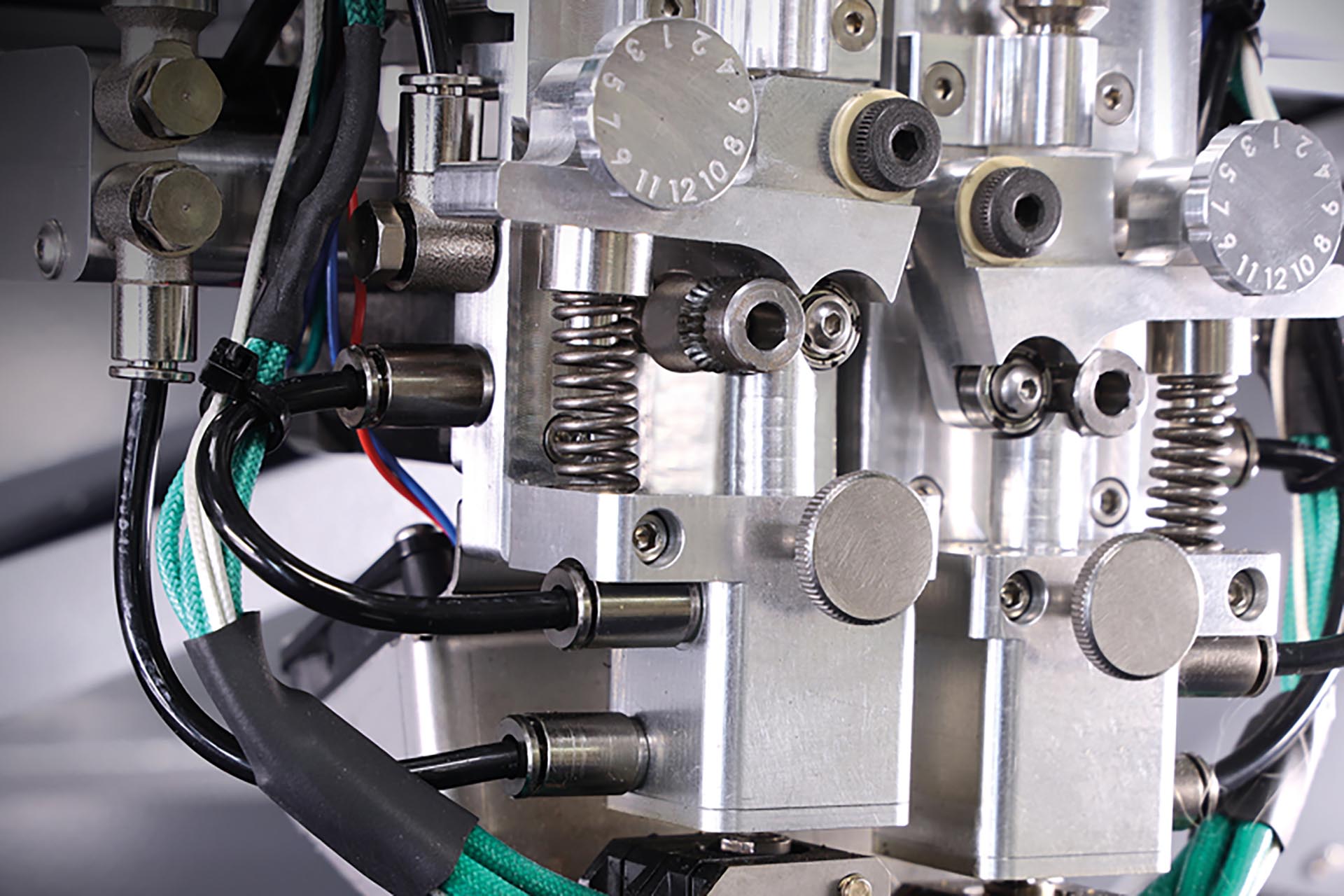

An extremely sturdy steel frame and high-quality components form the basis for optimum use in industrial continuous operation.

|

|

|

||

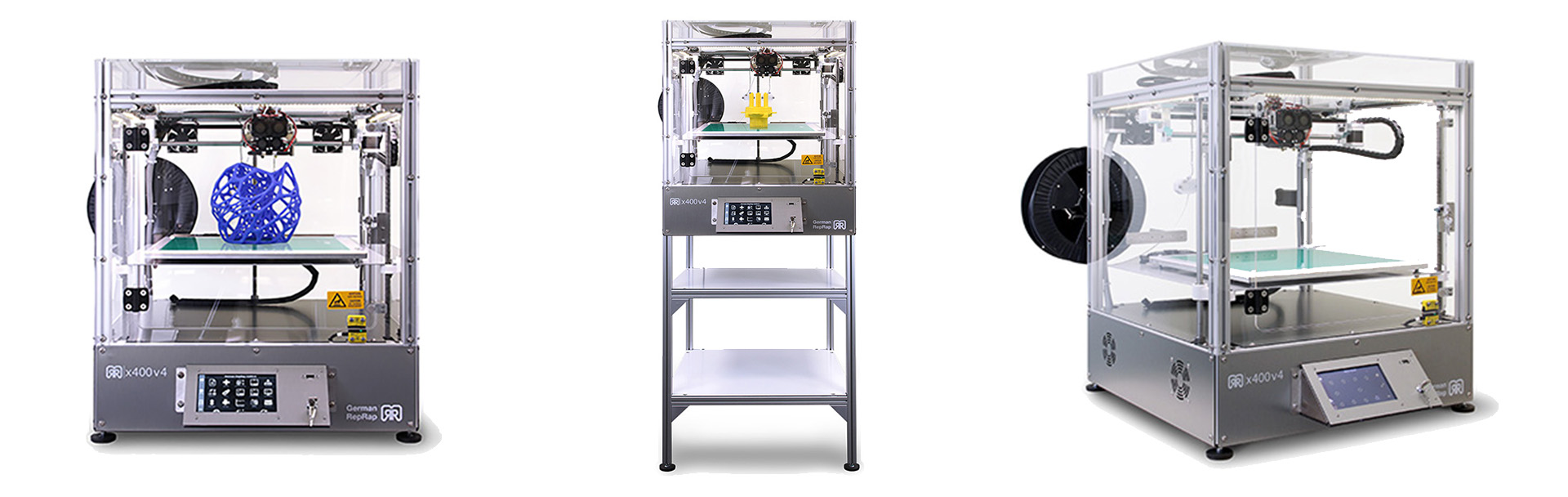

| Optimal Build Platform | Industrial Design | Auto Bed Leveling | ||

| With its build platform of 350 x 400 x 310 mm (15.4 x 15.7 x 12.2 in), the x400 v4 enables dual printing of large objects in one process as well as small series with industrial quality. | The x400 v4 impresses with a high-quality design in aluminum optics and is not only fast, but also prints precisely with a layer resolution of up to 0.1 mm. In doing so, he scores first and foremost with his high running stability. High-quality components with exact drive technology and milled metal elements ensure high process reliability and deliver a machine with industrial quality. | The print bed is adjustable in height by the Auto Bed Leveling function and has to be calibrated only once. Time-consuming adjustment of the print bed before each print job is no longer necessary. | ||

|

|

|

||

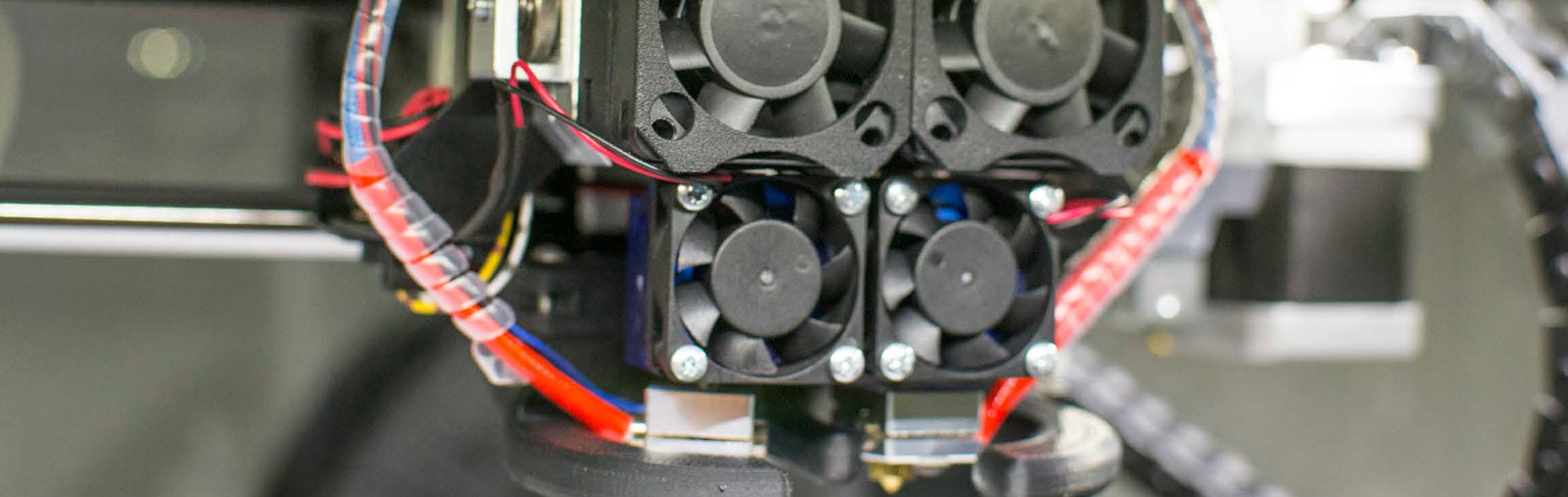

| Professional Ventilation Concept | Software: SIMPLIFY3D | Electronics for demanding users | ||

| The x400 v4 is equipped with the new German RepRap fan KIT to ensure equal temperature control, which has a positive effect on the process reliability. The extruder ventilation ensures an optimum temperature at the extruder, while the object ventilator and the assembly space ventilation ensure an optimum object and ambient temperature. | One integrated software suite contains everything you need to print high quality parts. Customizable settings and advanced processes put the controls into your hands. Support for dual-extruders, multi-part printing and even multiple processes within one part. Included in scope of delivery. | The x400 v4 is equipped with an industrial computer and can be operated via a touch-screen as well as via a USB interface (stand-alone printing). The network connection is made via Ethernet with browser-based control. | ||

|

|

|

||

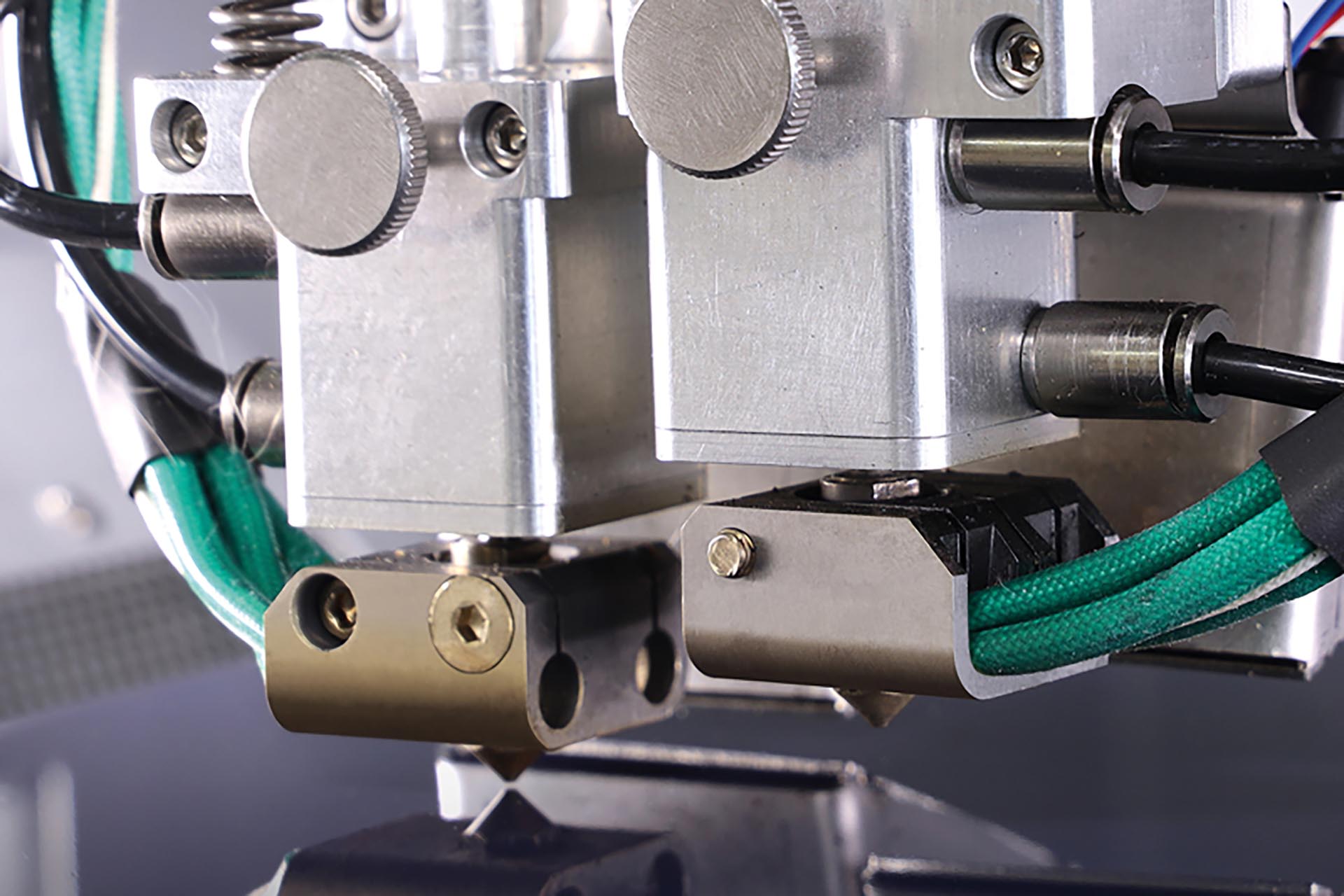

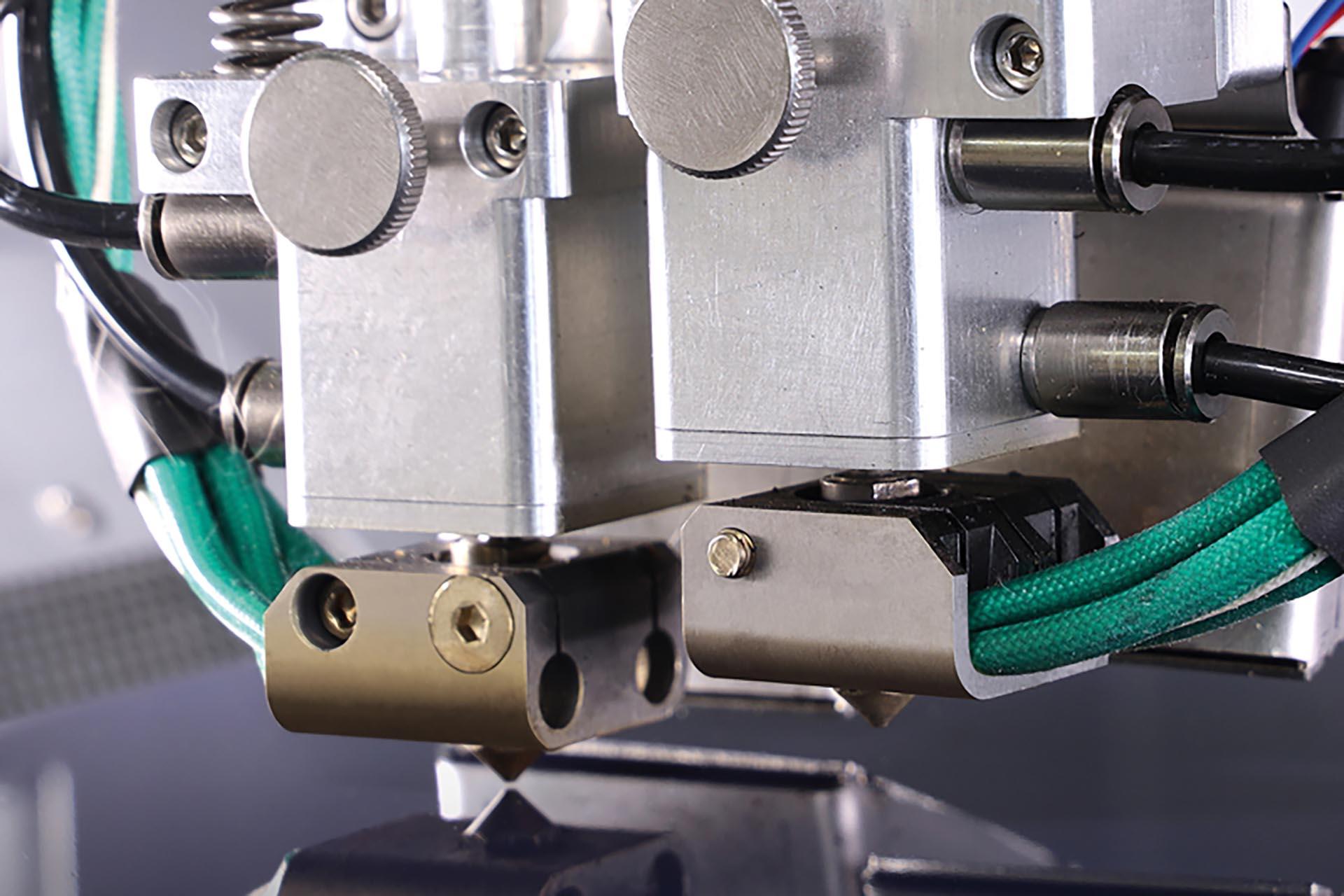

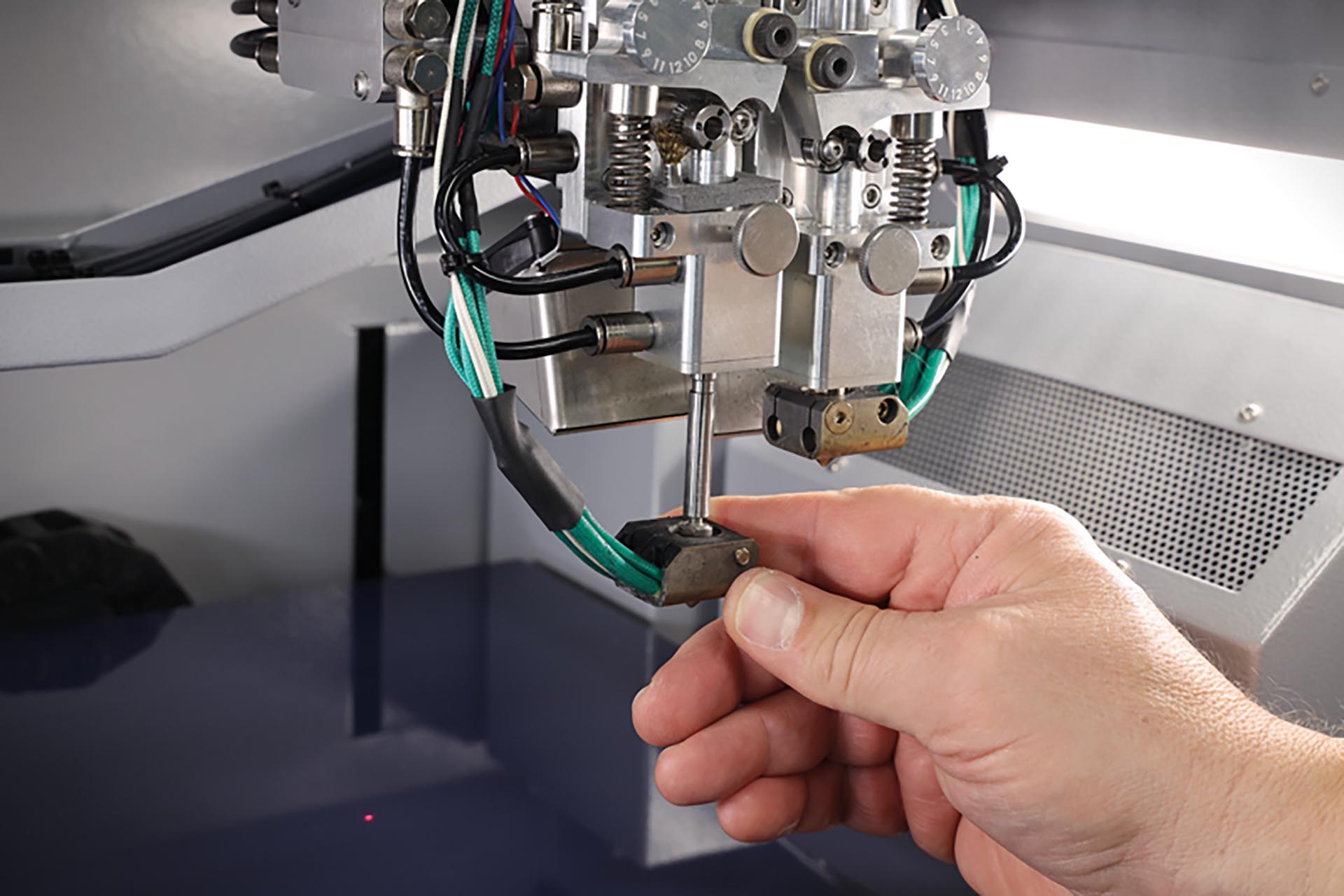

| Hotend and Extruder | Filament Tracking System | Maintenance and Service | ||

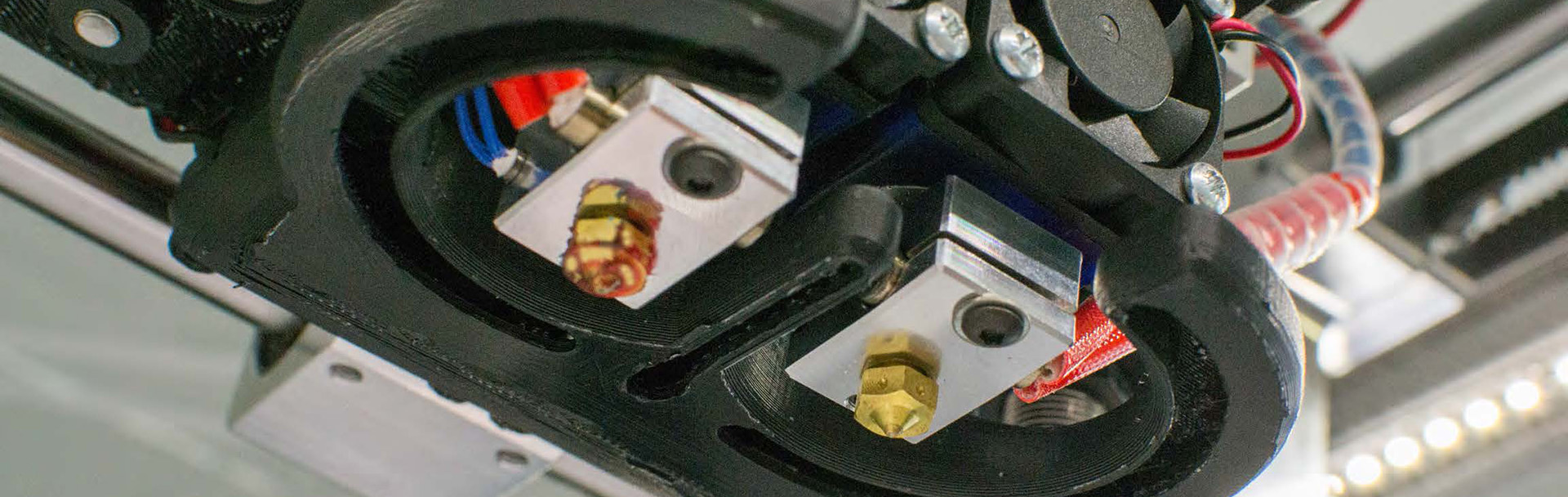

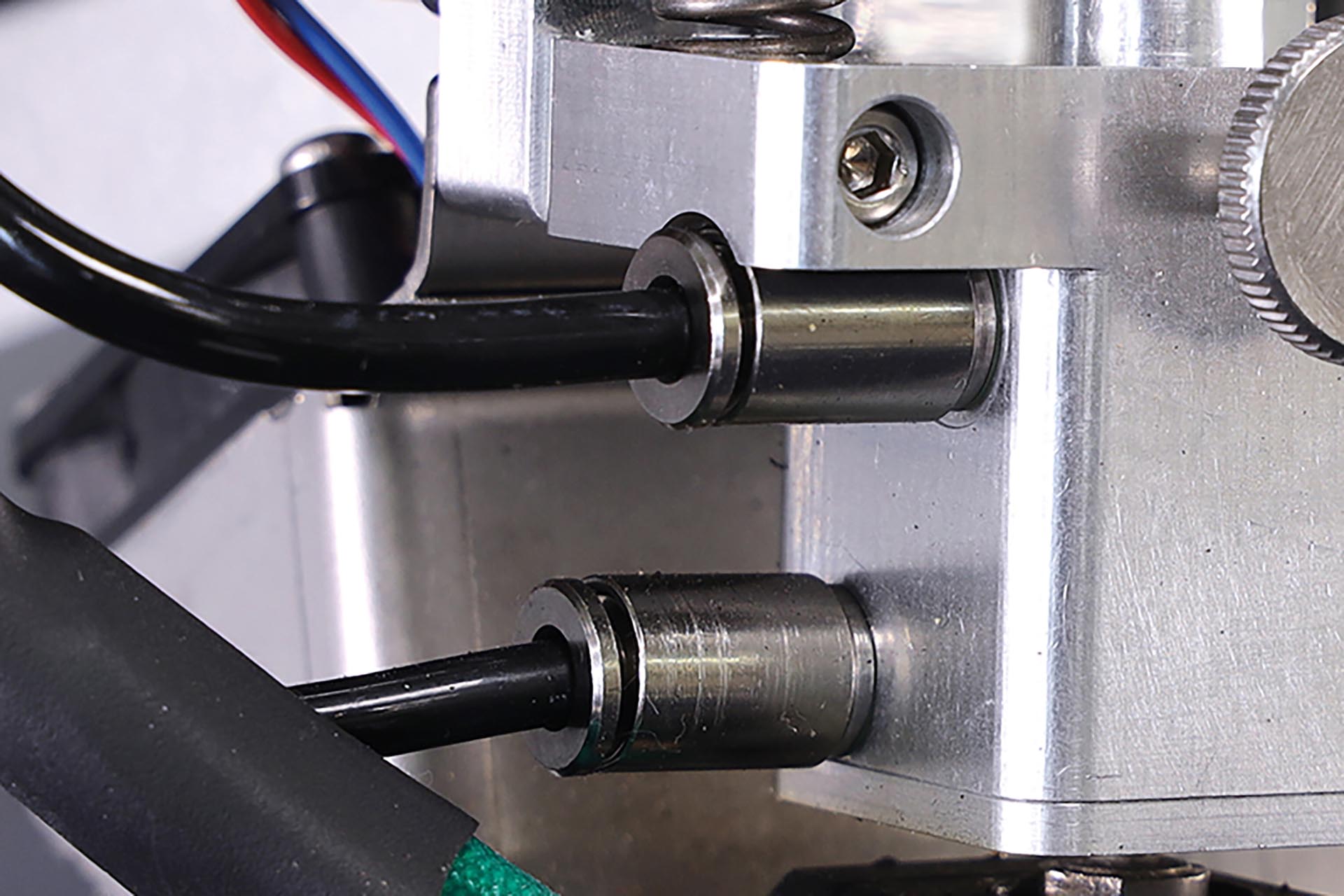

| The x400 v4 works with the DD3 Dual Extruder technology. The DD3 extruder and full-metal hotend are easy to use. Re-adjustment is not necessary. The extruder can be equipped with different nozzles, depending on the application and the materials to be used. The contact pressure can also be varied, which facilitates the processing of softer materials. | Using the Filament Tracking System, the x400 v4 automatically pauses the current print job when the filament is empty. In addition, the x400 v4 detects a deviation of the extrusion or conveying speed which is not visible to the naked eye and can react to the process reliably and thus actively prevent a print job break. | The x400 series has proven its reliability in continuous operation. Tailored to the needs of industrial use, the customer is optionally offered a maintenance contract as well as professional on-site service by a trained technician. The worldwide German RepRap partner network ensures a reliable service through a personal contact person. |

|

|

|

||

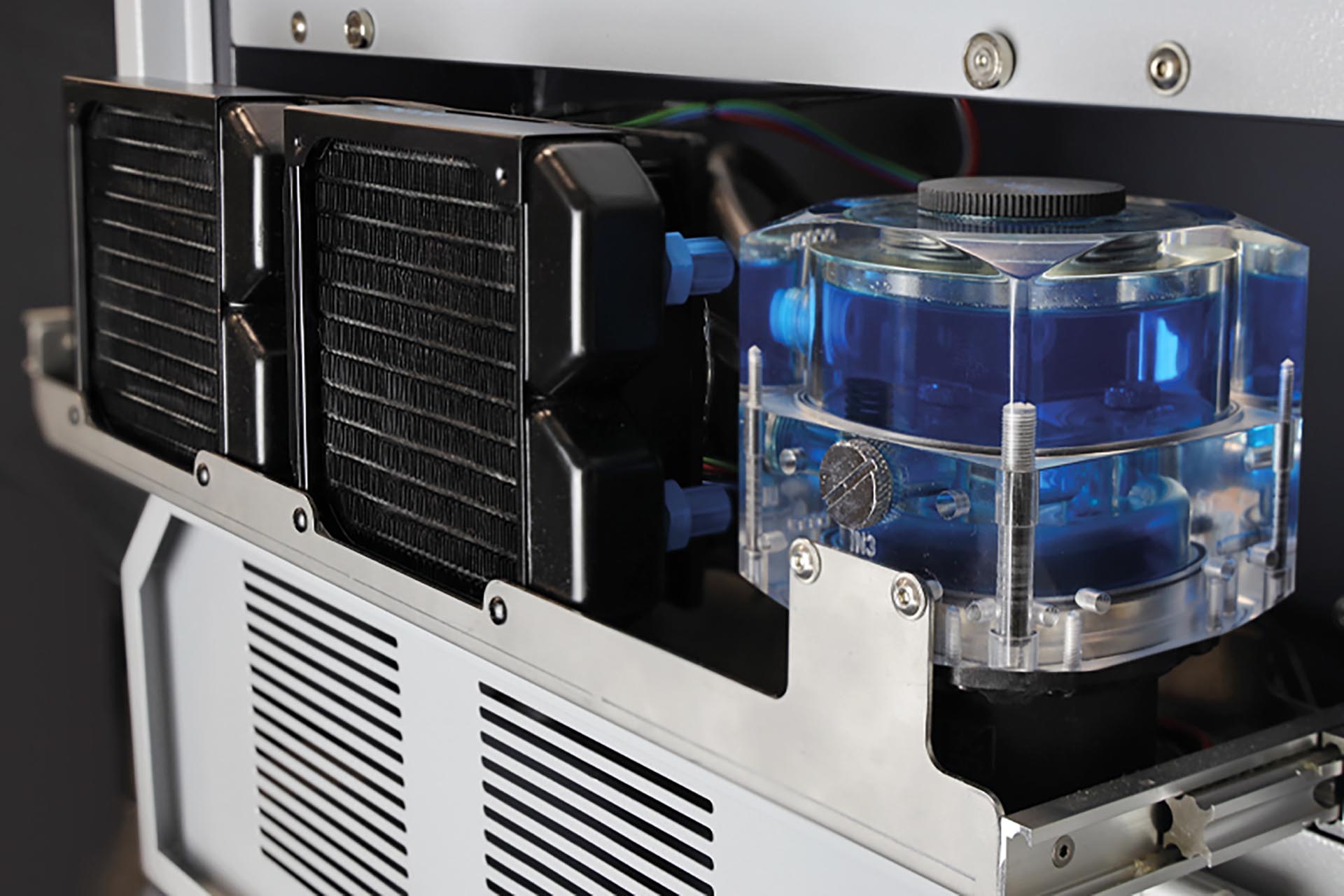

| Safety concept in accordance with industry standards | Professional cooling concept | Maintenance and service | ||

| The x500pro is designed with a comprehensive safety concept in accordance with industry standards. The foot switch enables controlled, safe system interventions while the process is in operation. This can be used to make precision adjustments to the control circuit for the printing parameters, for example. | The object ventilator and build area ventilator with filter produce the ideal temperature for the object and its environment. This prevents bulging or warping even when heat-sensitive materials are used. | The x500pro has proven to be reliable in continuous operation. An optional maintenance contract is available that is tailored to industrial application needs, and professional on-site servicing by trained technicians is also on offer. In addition to maintenance and repairs to the 3D printer, this includes software and hardware training. Individual details can be discussed at any time. |

Technical details

| Modell | x500 PRO |

|---|---|

| Printing area* | (X/Y/Z) 500 x 400 x 450 mm / 19.7 x 15.7 x 17.7 in |

| Print speed* | 10 - 150 mm/s |

| Traverse rate | 10 - 300 mm/s |

| Repeat precision* | (X/Y) +/- 0,02 / 0,05 mm |

| Thickness* | (min.) 0,02 mm |

| Filament / nozzle diameter | 1,75 mm / 0,40 mm |

| Nozzle options* | 0,25 | 0,30 | 0,35 | 0,50 | 0,60 | 0,80 mm |

| Material* | (Filament) information on consumables can be obtained via your contact at German RepRap. |

| Material supply | Material supply from four filament reels possible: one large (2.1 kg) and three small (750 g). One per printhead can be used by the printer. |

| Extruder | DD4 dual extruder with dual lift extruder system (water-cooled) |

| Extruder temperature (max.) | 400° C |

| Build area temperature | 80° C |

| Heated bed temperature | 150° C |

| Options | Base unit, industrial filament drying, annealing unit, maintenance contract |

| Data transfer | Stand-alone printing with highly sensitive touch display, USB stick and Ethernet |

| Software setup | Simplify3D |

| Supply voltage* | 230 VAC |

| Ambient temperature | 15-26°C |

| External dimensions | (W/D/H) 1120 x 850 x 955 mm |

| Weight | approx. 185 kg |

| Technology | FFF (Fused Filament Fabrication) |